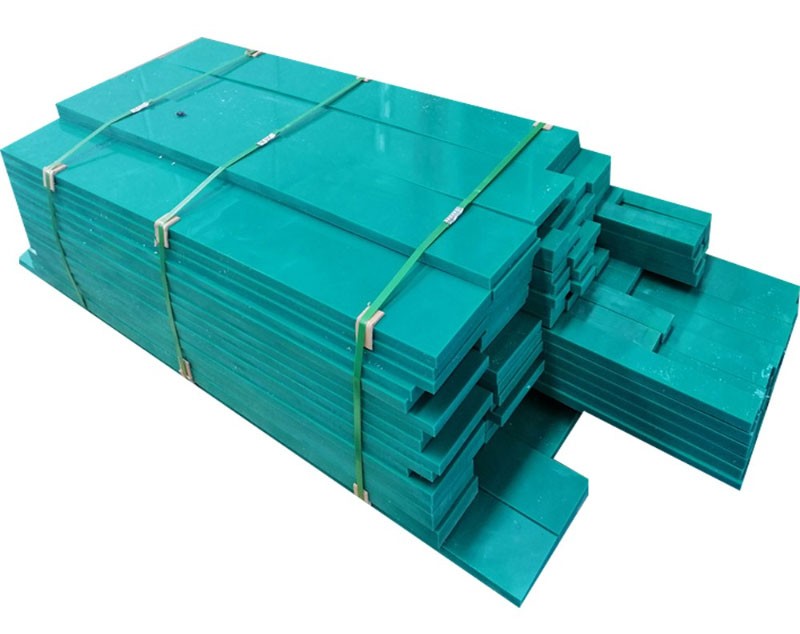

Dark green pressing UHMWPE strips

A: Features of uhmwpe strips

1. No water absorption

2. Non-Toxic

3. Low coefficient of friction

4. Self-lubrication

5. Low temperature resistant

6. Corrosion resistant

7. High impact resistant

8. High abrasion and wear Resistant

9. Excellent dielectric properties

10. Weatherproof

11. non-sticky

B: parameter list of uhmwpe strips

NO.

Test Items

Unit

Results

Test Basis

1

Tensile Yield Strength

Mpa

34.9

GB/T 1040-2006

2

Tensile Breaking Strength

Mpa

38.8

GB/T 1040-1992

3

IZOD Impact Strength

Kl/m2

137

GB/T 1843-1996

4

Elongation (sample size:80*10*4mm)

%

318

GB/T 1034-1998

5

Heat Deflection Temperature

°C

96

GB/T 1663-2000

6

Melting Temperature

°C

236

GB/T 1634-2001

7

Coefficient of Friction

---

0.01

GB/T 0006-2002

8

Ball Indentation Hardness

N/mm2

42.3

GB/T 3398-1982

9

Density

k/cm2

0.96

GB/T 1033-1986

10

Water Absorption

K/m2

0.01

GB/T 1034-1988

C: Application of uhmwpe flat strips

1. Chemical Engineering: Corrosion and wear resistantance mechanical parts

2. Thermal power: coal handling, storage of coal, warehousing chute lining

3. Coal processing: sieve plate, filter, U-underground coal chute

4. Concrete: cement raw and finished product silo silo lining

5. Grain: food storage or chute lining

6. Mining: sieve plate, chute linings, wear anti-bonding part

7. Food industry: starshaped wheel, transmission timing bottle screw, bearings, guiderollers, guides, slide blocks, etc.

8. Some kind of rubber fender panels and front face of rubber fender