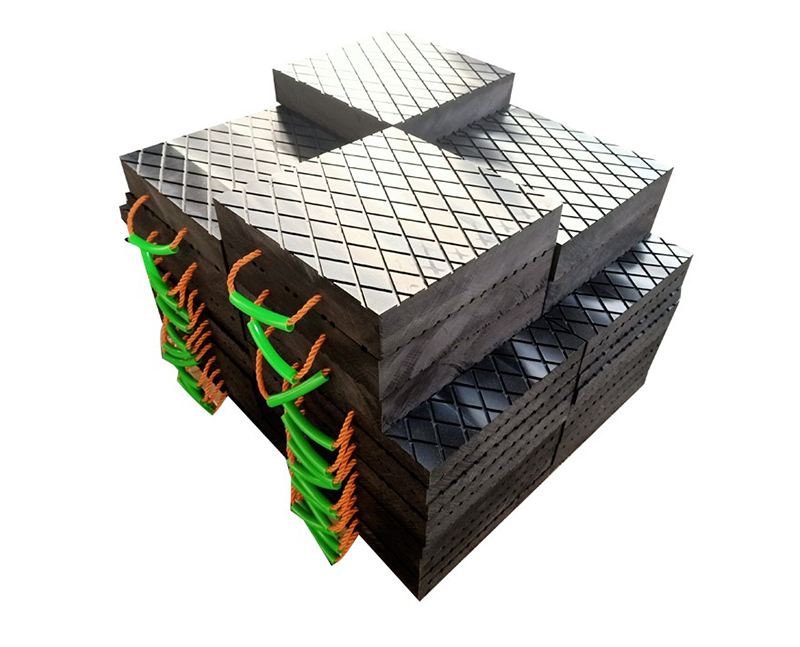

Outrigger pad:

Polyethylene outrigger pad is mainly used to pad under the outrigger of construction machinery for support.

Raw material: made of UHMW / HDPE polymer synthetic material.

Bearing capacity: 10-180 tons.

Specification and size:

450*450 500*500

550*550 600*600

800 * 800 1000 * 1000 unit: mm

Product advantages: compared with the traditional metal leg pad, the polyethylene leg pad has lighter weight, chemical corrosion resistance and good stability. It can bend rather than break when overloaded, and has extremely high strength and stiffness, providing more stable support for large-scale construction machinery.

Product function: it is mainly used to pad under the legs of pump truck, crane and fire truck to support partial pressure.

Outrigger pad is mainly used to pad under the outrigger of construction machinery and play a supporting role. This material has high strength and stiffness, which can reduce the deformation of the base plate body under stress and provide more stable support for construction machinery. Water resistance, zero water absorption and corrosion resistance. This material will not split or corrode. It can replace the traditional substitutes of wood and steel, which greatly saves the use cost and improves the work quality.

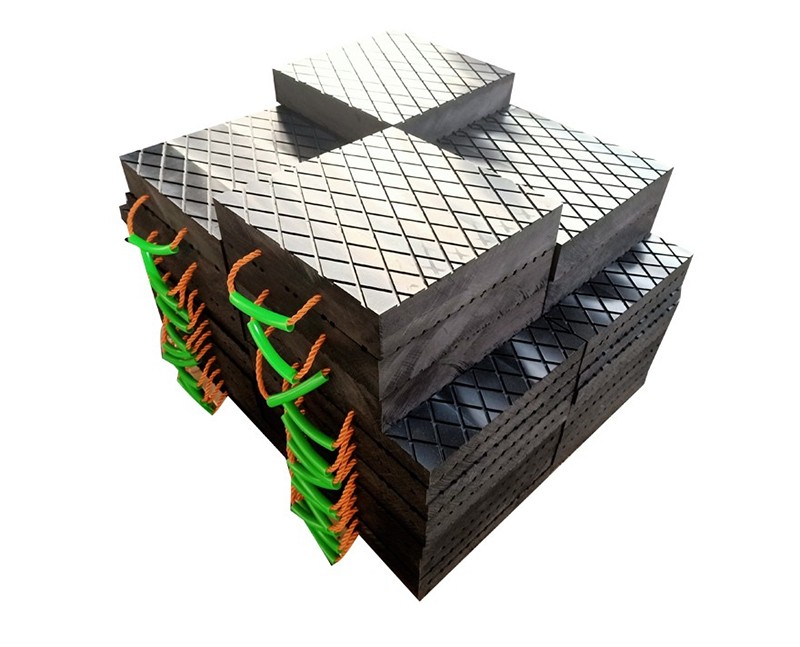

The four corner support of outrigger base plate can be used normally in harsh environment, and it is better to bend without breaking in case of overload. The portable rope is made of nylon, and the end of the portable rope is embedded in the base plate body to facilitate transportation and arrangement. The process composite UHMWPE leg pad is formed by pressing and processed by NC machine in the later stage.