UHMWPE Profiles&parts Characters:

1. High-wear resistance seven times wear resistance than steel, four times than PTFE.

2. High impact resistance two times impact resistance than PC, five times than ABS.

3. Self-lubrication the same as PTFE, better than steel and brass appended lubricating oil.

4. Anti-corrosion resistance, stable chemicals property and can endure the corrosion of all kinds of corrosive medium and organic solvent in certain rang of temperature and humidity.

5. Non-sticking the smooth surface of product hardly affixes other material.

6. Low temperature resistance in (-196), it still has the prolongation and high tensile strength.

7. Non-toxic and clean property

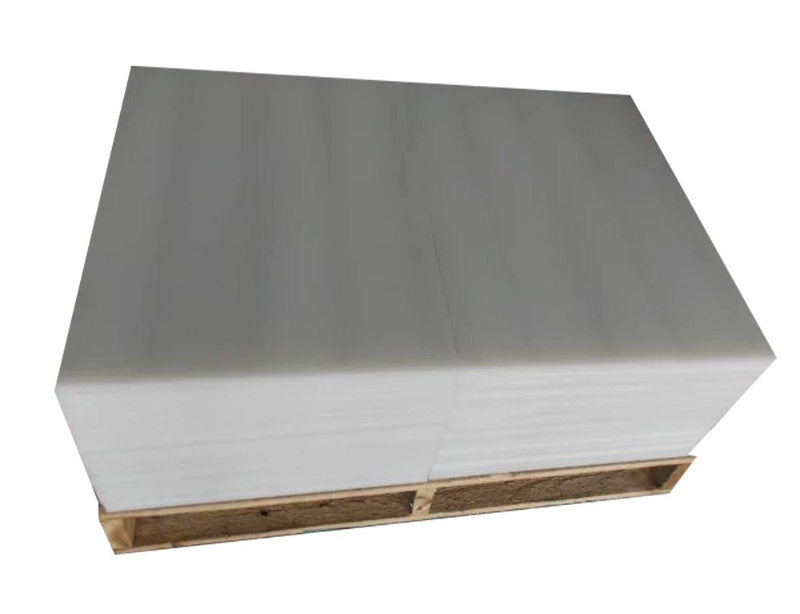

UHMWPE Specifications:

Property

Unit

Value

Density

g/cm3

0.93-0.96

Average molecular weight

g/mol

3million- 10 million

Tensile strength (23°C in air)

MPa

22

Breaking strength

MPa

42

Tensile strain at break

%

600

Charpy impact strength (notched)

mJ/mm2

No break

Ball indentation hardness

N/mm2

42

Shore D hardness

--

65-70

Abrasion

%

70-80, steel = 100

Static Friction Coefficient

--

≤0.16

Kinetic Friction Coefficient

--

≤0.10

Water Absorption

--

NIL

Elongation at break at 23 degress

%

≥300

Temperature resistance

°C

-269 to +85

Melt Temperature

°C

130-140

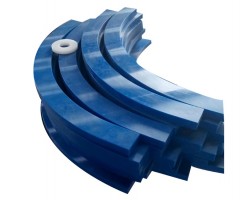

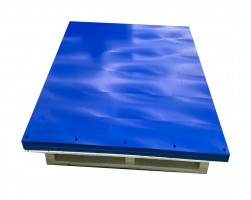

We offer an extensive range of extruded and machined plastic profiles and German UHMWPE Wear Strip such as under chain track profiles, plastic wear strips and plastic conveyor chain tensioner for use in power transmission, conveying, elevating and in materials handling applications. Traditional steel guide profiles lead to heavy wear on steel chain links plates and rollers, requiring constant lubrication. UHMWPE Wear Strip can offer unique sliding and low wear properties to help resolve these problems.